Computers have had a profound impact on the producing enterprise, revolutionizing the manner merchandise is produced and improving efficiency, productivity, and excellence. Automation and robotics, empowered by using computer systems and superior technologies, have converted production procedures, making them more streamlined, precise, and scalable. In this post we are able to discover the big impact of computers in manufacturing, specially specializing in automation and robotics.

Automation

Computers are instrumental within the automation of manufacturing procedures, bearing in mind the seamless integration of various duties and decreasing human intervention. By utilizing automatic manipulation systems and programming, repetitive and mundane tasks may be executed by using machines, improving each pace and accuracy. From assembly traces to fabric managing, computer systems permit the automation of complex operations, mainly to expand efficiency, decrease errors, and decrease production time.

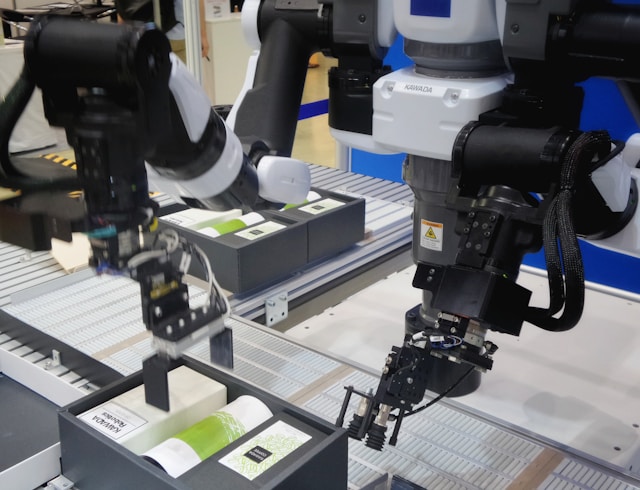

Robotics

Computers have facilitated the sizable use of robots in production. Robotics, powered via superior algorithms and artificial intelligence abilities, allow machines to carry out an extensive range of tasks with precision and consistency. Industrial robots can take care of problematic operations including welding, portraying, meeting, and pleasant management. With the assistance of laptop sensors and imaginative and prescient structures, robots can adapt to changing environments and make real-time adjustments, ensuring product high-quality and performance, https://www.leroijohnny.co/fr . This has transformed the producing industry via increasing productivity, removing production bottlenecks, and enhancing worker safety.

Benefits of Computer-Based Manufacturing:

Increased Productivity

Computers, automation, and robotics have significantly elevated production productivity. Machines can perform constantly and reap excessive production prices at the same time as keeping regular first-rate. This lets corporations provide goods at a larger scale, meet market demands greater efficiently, and gain cost savings.

Improved Quality Control

Computers and superior algorithms allow actual-time tracking and quality manipulation at some stage in the manufacturing method. Sensor systems and device imaginative and prescient technology allow for accurate inspection, decreasing defects and ensuring consistent product great. This ends in customer pleasure, stronger logo popularity, and decreased waste and fees associated with transform or recalls.

Enhanced Workplace Safety

Computer-primarily based manufacturing reduces the reliance on human labor in unsafe or bodily demanding responsibilities. Automation and robotics take over such roles, minimizing the danger of injury to people. With machines performing repetitive, heavy lifting, or risky operations, human people can recognize more complex duties that require creativity, problem-solving, and crucial thinking abilities.

4. Customization and Flexibility: Computers have facilitated the implementation of flexible production systems, permitting manufacturers to respond quickly to converting customer needs. With pc-managed automation, product customization and model can be completed greater efficiently, permitting corporations to meet personal client preferences and brief manufacturing runs.

Challenges and Considerations

Workforce Adaptation

The integration of computers, automation, and robotics calls for a skilled team of workers that could operate and maintain those systems. Ongoing education and upskilling of people are necessary to adapt to the evolving technology and make certain foremost usage of computer-primarily based production approaches.

Cost of Implementation

Implementing laptop-based totally manufacturing systems, such as automation and robotics, can contain vast upfront costs, inclusive of infrastructure, equipment, and software program development. Companies need to assess the return on funding and carefully plan their transition to pc-based total manufacturing to obtain long-term benefits.

Cybersecurity

With accelerated reliance on computers and interconnected structures, cybersecurity becomes an essential challenge. Protecting production facilities from cybersecurity threats, data breaches, and capability disruptions to operations is important in making sure the easy functioning of pc-primarily based production systems.

Conclusion

Computers have revolutionized the manufacturing enterprise, particularly through automation and robotics. By harnessing the power of computer systems, production procedures have come to be greater green, productive, and scalable. The blessings of pc-primarily based manufacturing consist of increased productivity, advanced exceptional control, stronger place of job safety, and extra customization and versatility. However, addressing challenges associated with workforce variation, price, and cybersecurity is crucial for accomplishing the full ability of laptop-based production. With persisted improvements in technology, computer systems will continue to play a crucial function in shaping the destiny of manufacturing.